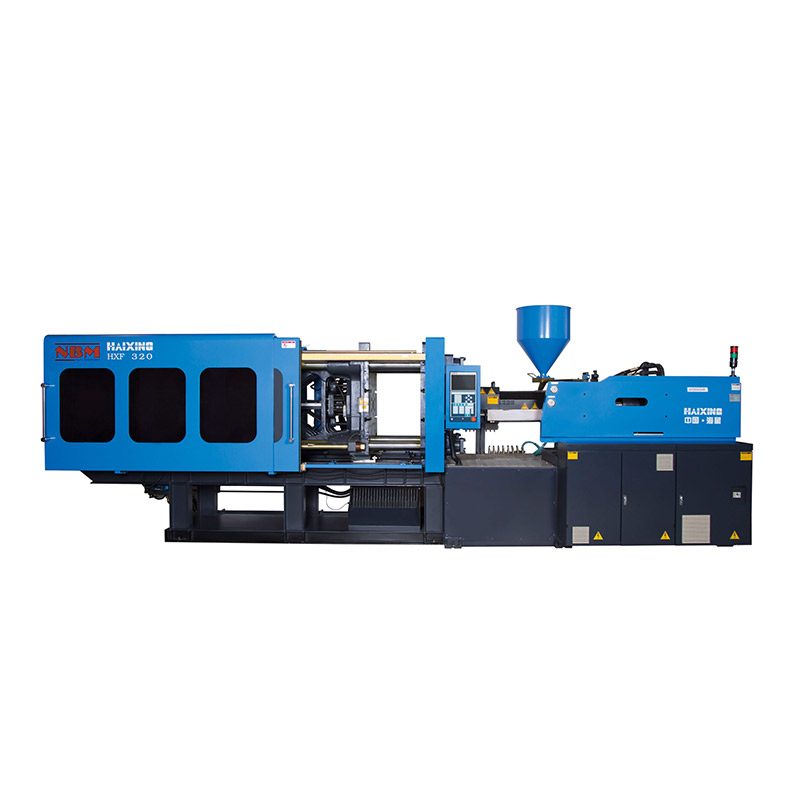

HXFJ5 injection molding machines – servo motor

HXFJ5 injection molding machines – servo motor

Low energy consumption

- After-Sales Service Nation-Wide

- 24-Hour Response And Quick Service

- Supplying Original Parts and Spare Parts

- Specialized Training for Customers

- Over Two Decades of Industry Experience

- Over Two Decades of Industry Experience

- Consulting 0 to 100 Plastic Injection Lines

Servo-Driven Energy-Saving Injection Molding Machines: The energy consumption of servo-driven injection molding machines is much less than normal machines with Ac motors, because pump generates output oil volume according to the desired speed. In the phase of holding, servo motor rotates at its minimum speed (almost stall mode) and consumes significantly less energy. Servo-driven energy-saving injection molding machines will save 30%-80% energy and ensure your economic prosperity. The response time of the drive system is astonishingly low, it requires only 0.05s to reach the maximum power output. Cycle time is substantially shortened compared with Ac motor-driven injection molding machines resulting in considerably improved efficiency. The precision of produced parts are greatly increased in machines equipped with servo motors compared with traditional hydraulic machines using either a fixed or variable pump. Repeatability of injection molding machines are 40-130% improved when equipped with servo motors.

Get a Free Consultation to Select the Right Machine!

Register your contact information to receive a prompt call from NBM's Sales Department.

Reviews

There are no reviews yet.