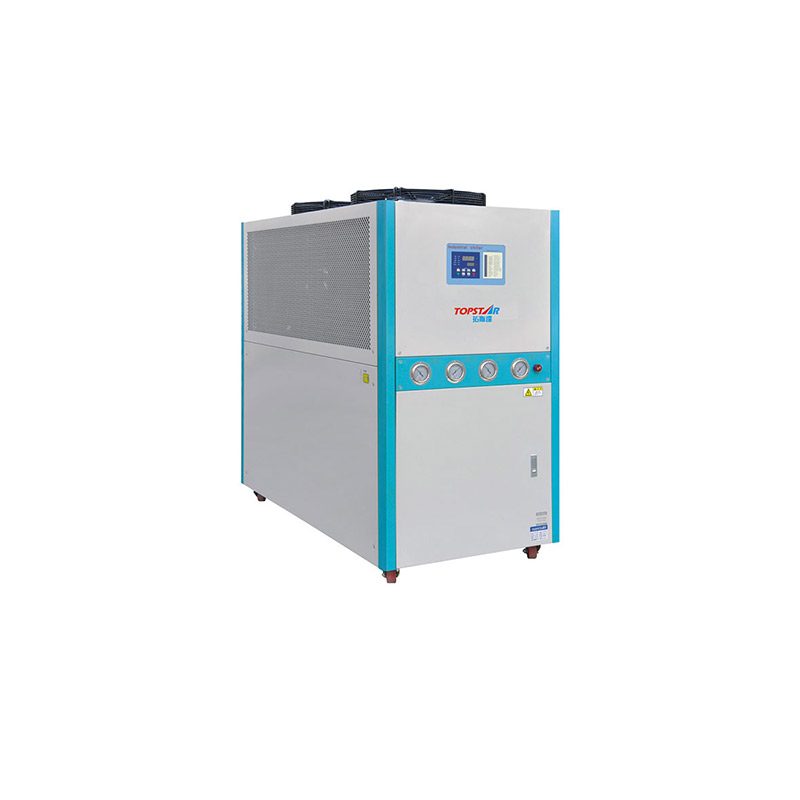

Industrial air-cooled chillers

Industrial air-cooled chillers

An air-cooled chiller works on the basis of vapor compression or absorption refrigeration cycle and they use ambient air for dissipating the absorbed heat from the evaporator unit. Cold water produced by the chiller have different uses such as air conditioning or cooling industrial machinery. In the process of injection molding there are 2 main uses for the cold water which are to control injection unit temperature and mold cooling.

Cooling time takes the major part of production cycle time which is the transformation of part from liquid to solid. Hence by using the most appropriate cooling method, desired production rate can be achieved.

- After-Sales Service Nation-Wide

- 24-Hour Response And Quick Service

- Supplying Original Parts and Spare Parts

- Specialized Training for Customers

- Over Two Decades of Industry Experience

- Over Two Decades of Industry Experience

- Consulting 0 to 100 Plastic Injection Lines

Industrial air chillers features:

- Powered lack-phase protector with signal light indication.

- Main switch sensitive to electricity flowing out.

- Compressor protector from ice particles.

- Compressor rolling back protector with signal light indication.

- Pump rolling back protector with signal light indication.

- Compressor overload protector with signal light indication.

- pump overload protector with signal light indication.

- Chillers high voltage protector with signal light indication.

- Compressors low voltage protector with signal light indication.

- Compressors time-delay start safeguard.

- Using high-quality compressor, so it is very safe and noiseless in addition to providing satisfactory energy saving and durability.

- Using Italian temperature controlling unit, it can control the temperature between +5C to +35C with the accuracy of ± 1C.

- Unique design of the chiller and its radiator impressively increased the heat exchange efficiency.

- Stainless steel temperature-holder box, convenient for cleaning.

- Temperature of ultra-cod chiller can be below -15 C.

NBM chillers can provide 3 to 15 tons of refrigeration capacity, if higher refrigeration capacities are needed, then order must be placed.

There are different types of chillers for cooling operation of injection molding and blow molding machines. Choosing the right equipment and determining the right amount of heat transfer in the cooling procedures require precise calculation by professional engineers and Nekoo Behineh Machine can provide consultation based on customers need.

Get a Free Consultation to Select the Right Machine!

Register your contact information to receive a prompt call from NBM's Sales Department.

Reviews

There are no reviews yet.